Label Applicators

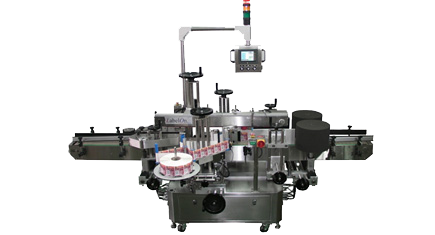

The LabelOn™ Modular represents a machine concept born from extensive labeling experience.This experience involved design, sales, and overseas distributor establishment. Distributors in over a dozen developed and emerging economies enjoyed remote servicing, sales support and frequent visits.

What you are seeing is the result of that experience – the LabelOn Modular label applicator. It is a labeler that can be sold and represented throughout the world. This machine is manufactured and configured in modules to cover a vast majority of the most common labeling tasks.

What you are seeing is the result of that experience – the LabelOn Modular label applicator. It is a labeler that can be sold and represented throughout the world. This machine is manufactured and configured in modules to cover a vast majority of the most common labeling tasks.

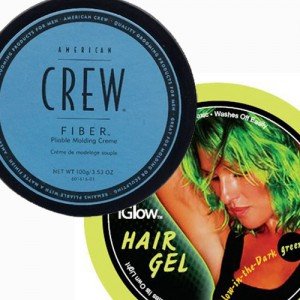

This LabelOn Modular machine has modules available to label front and back labeling of Flat Sided Bottles , Oval Sided Bottles and Round Bottles or Jars.

The Round products can have a single label of up to 100% Wrap label. The Round bottles can also have their label or labels placed; orientated to a reference feature or mark like a bottle handle or a pre-existing label.

Extra Labeling System

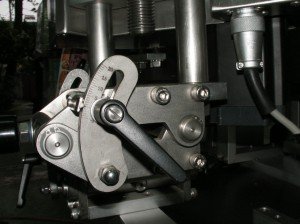

Adding to this impressive configuration of modules is the Extra Labeling System or E.L.S. – seen here ready to label  the top of a product as it passes through the LabelOn Modular machine. On its own the ELS is an impressive piece of labeling equipment, capable of placing spot labels from Above, the Side or On to angled panels like necks of bottles. The ELS can be wheeled up to existing conveyor lines to work in a Stand-Alone Capacity. However, the real ingenuity of the ELS is its design to “dock” with the LabelOn modular machine and synchronize to the modules of the main machine. Even its controls are passed over to the Main LabelOn modular unit.

the top of a product as it passes through the LabelOn Modular machine. On its own the ELS is an impressive piece of labeling equipment, capable of placing spot labels from Above, the Side or On to angled panels like necks of bottles. The ELS can be wheeled up to existing conveyor lines to work in a Stand-Alone Capacity. However, the real ingenuity of the ELS is its design to “dock” with the LabelOn modular machine and synchronize to the modules of the main machine. Even its controls are passed over to the Main LabelOn modular unit.

Clients, like contractors with multiple lines, will appreciate having one or two ELS systems that can dock in minutes to one of their more numerous LabelOn Modular machines for when promotional spot labels are required; say on the neck of the bottle or even its cap.

For a given labeling task the required modules integrate smoothly and present a machine that has the adjustments and feel of a machine that was dedicated to that task. Adjustments are easy to make and self-evident in most cases. These adjustments are easy to record and replicate for future runs.

Labeling Machine Support System

Extensive 3D mechanical records, and comprehensive electrical records of each machine enable over the phone and internet based sessions to quickly identify service items or parts. To date, we have not come across a service requirement where a LabelOn technician had to attend on site; it was all handled remotely.

The LabelOn Modular Machine offers:

- Unprecedented versatility and upgrade paths

- Technology utilised to the fullest for machine service and support

- Intuitive and predictable machine adjustments and

- Amazing value for this level of labeling equipment